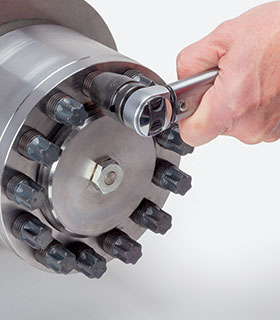

PF Flex Nuts (passive round nuts)

PLOKE PF Flex nuts are elastically resilient and are generally used on Radial Pretensioning Bolts (RPB) for bores < ø80 mm and on high-strength bolted joints with short clamping lengths as reactive nuts on the "B-side" of the RPB.

Under load, the part on the load side expands and the upper, slimmer part contracts. This reduces stress peaks and increases the fatigue strength of the connection. For this reason, Flex Nuts are also used wherever fatigue fractures in bolted connections are to be feared.

Flex Nuts are only to be used as reactive nuts and must not be torsionally clamped.

PLOKE PF Flex Nuts are individually designed for the respective application – please contact us.